TERVAKOSKI FILM HAS A SUITABLE FILM ALTERNATIVE FOR EVERY CAPACITOR TYPE AND APPLICATION.

FOR DRY CAPACITOR STRUCTURES, WE OFFER EITHER METALLISED FILMS WITH DEMANDING RESISTIVITY PROFILES OR BASE FILMS FOR METALLISATION, SUCH AS TERVAKOSKI FILM ECT CAPACITOR FILM. FOR THE CLASSIC IMPREGNATED CAPACITOR DESIGNS WE OFFER RERTD HAZY FILM, WHICH IS DEDICATED TO DC APPLICATIONS AND RERT FILM FOR AC APPLICATIONS.TERVAKOSKI FILM GROUP’S HISTORY AS A LEADING GLOBAL BOPP CAPACITOR FILM

SUPPLIER IN HVDC AND HVAC POWER GRID APPLICATIONS DATES BACK TO THE MID-1980S.

Globally, the first long-distance HVDC transmission project using All Film/Al foil impregnated capacitor technology was the Itaipu hydropower plant in Brazil. Tervakoski Film was chosen as the film supplier for the project, as our hazy BOPP capacitor film met the service life requirements of the capacitor selected for the power plant. Even back then, our high-quality films lasted for more than 25 years in use.

Since the successful Itaipu delivery, our TFG capacitor films have been used especially in renewable energy projects around the world. The best known of these is the Three Gorges HVDC project in China, which is still the largest hydropower plant in the world.

The TFG film and the entire Tervakoski Film HVDC and HVAC power transmission product family have received only excellent feedback from the market. The recipe for success here is our experience gained from global projects combined with the optimisation of film properties and polymer parameters using the results of our own capacitor element testing, as well as verifying these with authentic testing performed during the manufacturing process.

TERVAKOSKI FILM ECT BASE FILM FOR METALLISATION– A HIGH-RELIABILITY HVDC SOLUTION FOR LONG ENDURANCE AND HIGH-STRESS REQUIREMENTS

Since the late 1990s, dry metallised film capacitors have been developed for durable, renewable applications such as wind, solar and hydropower. With the proliferation of HVDC transmission systems, for the first time, the base film and metallised dry structure had to meet the similar high-reliability requirements found in HV-impregnated film models.

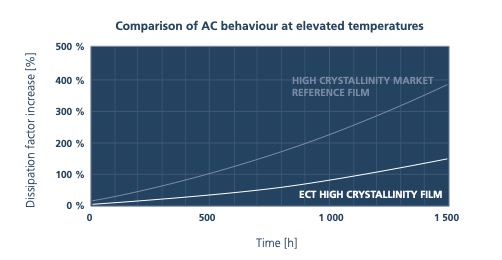

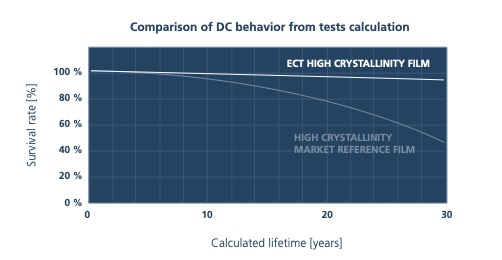

Therefore, at Tervakoski Film, we developed a product suitable for these applications. Our long experience and technical knowledge in HVAC and HVDC applications and the observed weaknesses in a standard high crystallinity capacitor film laid the foundation for a new, even better capacitor base film, called Tervakoski Film ECT base film for metallisation. We optimised its parameters to be safer in long-life HVDC applications. The focus was on the durability of the film in HVDC, but in addition, we took into account the presence of AC components as well as high-voltage and temperature stresses, which are typical ageing parameters in HVDC applications. The new ECT film was launched in 2013, and since then it has repeatedly fulfilled its performance in global HVDC projects.

In addition to demanding HVDC and HVAC applications, the unique properties of the ECT base film have also proven to be ideal for other challenging applications, such as automotive and traction applications, where greater reliability and maximum safety are required.